Panthergrip – Absolutely non-slip shin guard

22.03.2022

The Shark Tank of Patents

In season 7, episode 6, of the TV show "Die Höhle der Löwen" (German version of the US show Shark Tank and the UK show Dragon's Den), an independent developer presents a shin guard called PANTHERGRIP that offers faster donning and greater wearing comfort.

The PANTHERGRIP is a molded part that has thousands of microteeth that engage with the soccer socks to prevent the shin guard from slipping while playing soccer. In doing so, the PANTHERGRIP does not require Velcro or similar fasteners at all. Here, better freedom of movement is ensured. A European patent application has been filed for the PANTHERGRIP. This is intended to serve as an example to show how features of a claim are to be understood with regards to the prior art.

The following explains why a patent application should describe, in addition to the core of an invention, other structural and/or functional features related to the invention in order to successfully obtain a patent grant.

The patent application – (EP3669684A1)

Claim 1

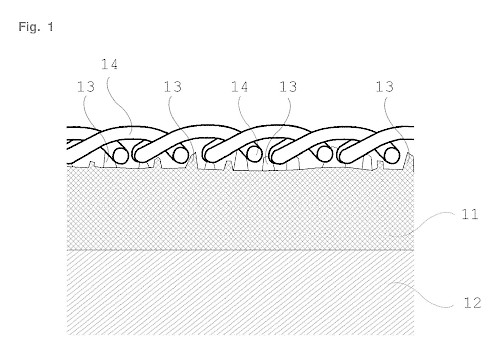

Originally, an attempt was made to protect the PANTHERGRIP as a body protection device. Claim 1 defines the following features M1-M3 (cf. reference signs from Fig. 1 below):

M1: Body protection device for athletes, in particular shin guards, the side of the body protection device facing away from the body having at least partially a surface (11) which contains a plurality of projections (13) which are adapted in size to penetrate into a textile, in particular into interstices between yarns (14) or into stitches of the textile of items of clothing normally worn over the body protection device, characterized in that

M2: the projections (13) have lateral surfaces which are at least partially oriented approximately at right angles to the surrounding surface (11), and in that

M3: the protrusions (13, 23) have a width or diameter of 0.02 to 0.8mm, preferably 0.1 to 0.4mm, the size of the protrusions (13, 23) corresponding to a grain size having the values of 1300 - 30, preferably 250 - 60.

Basic understanding of Claim 1

in other words

M1: The knobs (13) engage in the socks (14).

M2: The knobs (13) protrude from the surface (11).

M3: The dimension of the knobs (13) can be very small (0.02mm) to very large (0.8mm).

Search Report

In the search report, the examiner cited D1 (AR 2 551 190 A) as novelty-destroying for the subject-matter of claim 1.

Regarding M1:

D1 does not include any drawings, but also describes, as does the invention, a shin guard (cf. claim 34 of D1) that also does not use fasteners and provides a rough surface formed by corresponding wood particles that can frictionally engage the user's socks. Thus, at least feature M1is disclosed in D1 (cf. page 21, lines 7-10 of D1).

Regarding M2:

The size and shape of the wood particles in D1 can be regular or irregular. It is not explicitly described in D1 that the wood particles protrude "at right angles" from the surrounding surface. But it can be assumed that at least one of the wood particles is also almost certainly oriented perpendicular to the surface due to the irregular arrangement. Thus, although D1 does not explicitly disclose feature M2, it implicitly anticipates it (cf. last paragraph on page 7 of D1).

Info: Lack of novelty can either result explicitly from an embodiment in the prior art, in that all features are clearly described therein. However, lack of novelty can also result implicitly from the fact that the skilled person, when carrying out what results from this embodiment in the prior art, inevitably arrives at a result that falls under the patent claim to be assessed, as in the present case with respect to feature M2.

Regarding M3:

On average, a dimension of the wood particles in D1 is more than 0.02mm, advantageously more than 0.1 mm, 0.4 mm or 0.5 mm, for example more than 0.6 mm. Since these values in D1 are within the range of values as defined by feature M3, D1 also discloses feature M3(cf. last paragraph on page 7 of D1).

Info: The specific anticipates the general. Thus, the general cannot be new compared to the specific. For example, with respect to characteristic M1, the general term "protrusions" cannot be new versus "wood particles". With respect to feature M3, the (general) value range "0.02mm to 0.8mm" cannot be new compared to the single value "0.1mm" as described in D1, because this (special) value is within the (general) value range.

Thus, claim 1 is not novel over D1.

Fallback positions

Fallback positions – a priori

If the core of the invention is anticipated by prior art mostly previously unknown to the applicant, as in the case of PANTHERGRIP, the applicant should have described suitable fallback positions in the patent application, whether in the claims or the description, in order to be able to specifically differentiate the invention from the novelty-destroying prior art in the examination proceedings.

Info: Reformulations that are introduced only in the examination proceedings and are not originally disclosed are in most cases and with high probability not allowed.

As a consequence for the applicant, it results that for the invention every possible distinctive feature should be defined in advance in the patent application.

Fallback positions – a posteriori

In the present case, when distinguishing the invention from the prior art, the focus should be on specifying features M1 and/or M2. This is because the fundamental idea of PANTHERGRIP is based on the specific orientation of the knobs away from the surface and the arrangement of the knobs along the (overall) surface to achieve a suitable grip of the socks. Whereas in D1, a random arrangement of wood particles provides a frictional connection to the socks, possibly in part as form fit.

For example, the applicant has defined the following distinguishing feature in the application documents that would provide effective delineation from D1:

"where the protrusions [...] are directly introduced by an injection molding process".

Since wood particles are described in D1, projections produced by an injection molding process cannot possibly be anticipated by D1. The fact that the skilled person would have to deviate from the basic idea of D1, namely the use of the friction-enhancing wood particles, in order to realize the injection-molded projections, speaks in favor of an inventive step starting from D1 as the closest prior art. The skilled person would always avoid such a deviating procedure.

Conclusion

When drafting the patent application, a large number of fallback positions should be provided in advance (a priori) in order to be prepared for unknown prior art in the examination proceedings. For this purpose, as many fallback positions as possible should be left over from the a priori fallback positions in order to be able to distinguish the cited prior art in the best possible way (a posteriori). For the PANTHERGRIP case study herein, an exemplary feature was pointed out that fully reflects the idea behind PANTHERGRIP and with which the applicant can effectively delineate the invention from the cited prior art.

To enable such a positive initial situation, a targeted dialog between an experienced patent attorney and the inventor is essential for preparing the application documents. Here, essential product/feature details can be discussed and analyzed in order not to neglect important information a priori in the patent application, which may become important a posteriori.

Disclaimer: The above contribution reflects the personal opinion of the author. The assessments and statements made in the article do not constitute legal advice and are provided under exclusion of any liability. If you need an assessment of an individual case, please contact the author and/or the law firm KUHNEN & WACKER.

Further news and

publications from K&W

Start Your Career at K&W

and Become Part of Our Team

Are you ambitious and flexible? Do you like to work independently and are prepared to take responsibility? If so, K&W is your place to be.

Our HR manager Elwine Kaschner looks forward to receiving your application.